GESOTEC's high-temperature cameras are designed for continous use in harsh industrial enviroments and come equipped with failsafe features for unrivalled reliability and long-life cycles.

Example videos of our camera installations can be found here.

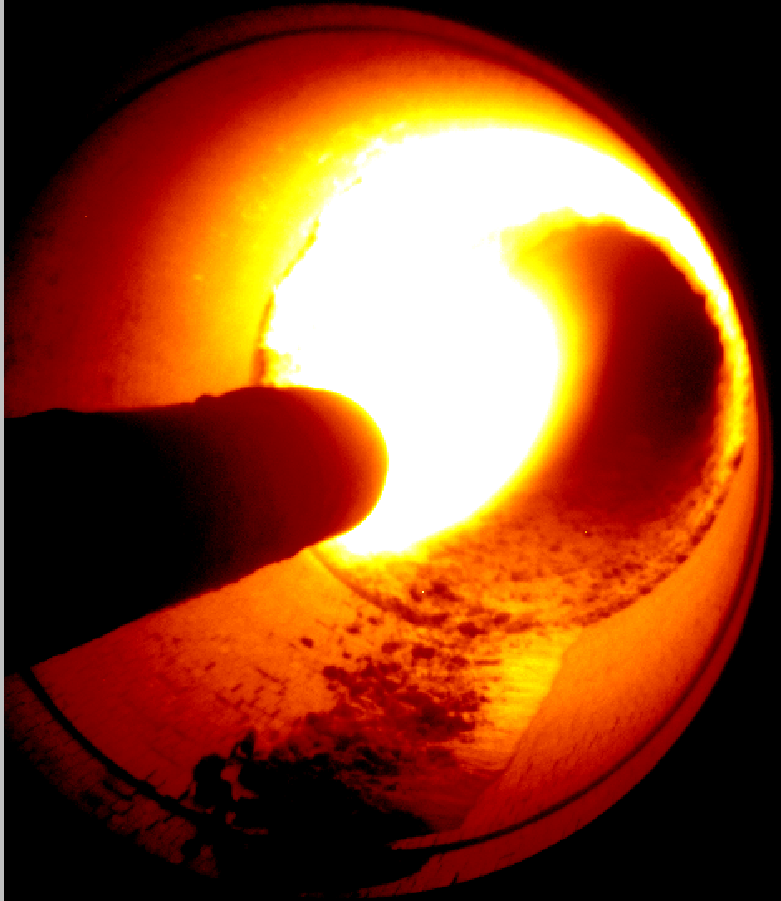

A good image starts with an appropriate optic. Our in-house optic designs deliver a high-definition, crystal-clear view of the high-temperature scenario. The use of state-of-the-art digital transmission based on industry-standard Gigabit Ethernet ensures a noise-free display without missing a single bit of quality.

Software features for image enhancement further improve the view and data evaluation.

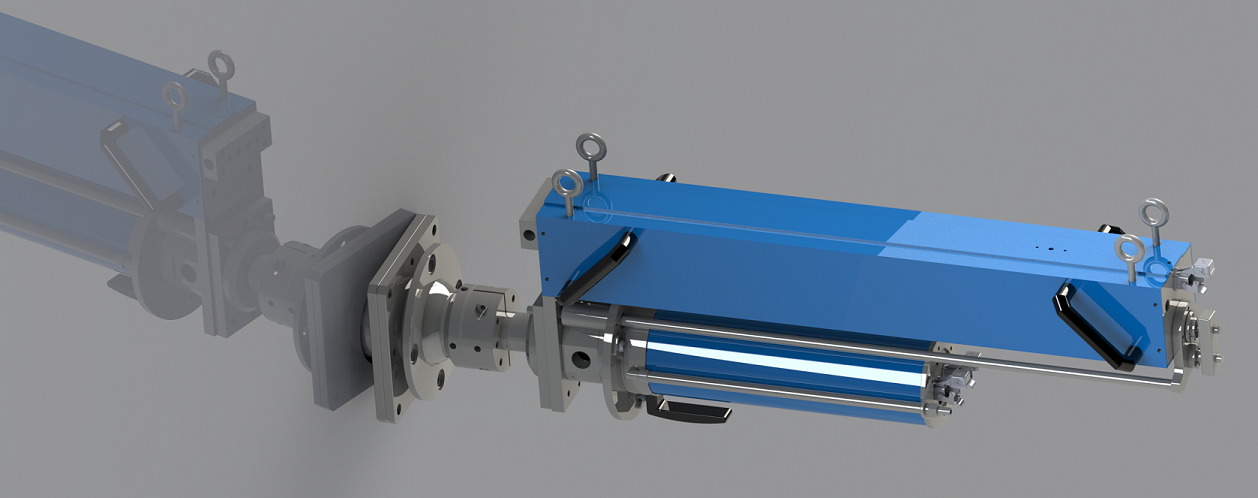

PyroViper™ "Infrared-TV" imagers and systems: Furnace camera solutions with tailored probe optics

Our PyroViper models with one, two or three built-in imaging sensors include a long air-cooled probe optic to get past thick furnace walls.

A range of lengths, fields of view and viewing angles are available. Custom-tailored solutions are also possible.

Depending on the application, the spectral range is adapted to visual (VIS), near infrared (NIR), short-wave infrared (SWIR), mid-wave infrared (MWIR) or long-wave infrared (LWIR).

Applications range from cement kilns and coolers or recovery boilers in paper plants to waste combustion and steel furnaces.

Check our best-seller, the PyroViper-3, here.

Or enjoy state-of-the-art visual and thermal monitoring with MWIR technology with the MWIR PyroViper-2.

For the pulp and paper industry, we offer an integrated system concept: Pulp and paper leaflet

FireEye™ High Temperature CCD-Camera Systems

For plain visual monitoring inside a furnace, our low-budget FireEye can be placed in front of an opening (or mounted to it).

The camera is not inserted and delivers just a narrow view.

GuardViper™: Camera systems for surveillance tasks

Our integrated visual and thermal monitoring concept includes the data acquisition and processing of Ethernet-based surveillance camera systems for full plant monitoring.